Filtration through a bed of sand is a cost effective way of removing suspended solids and other impurities in water treatment and wastewater purification. Nature itself employs the process and water engineers adopted it for practical use already in ancient times.

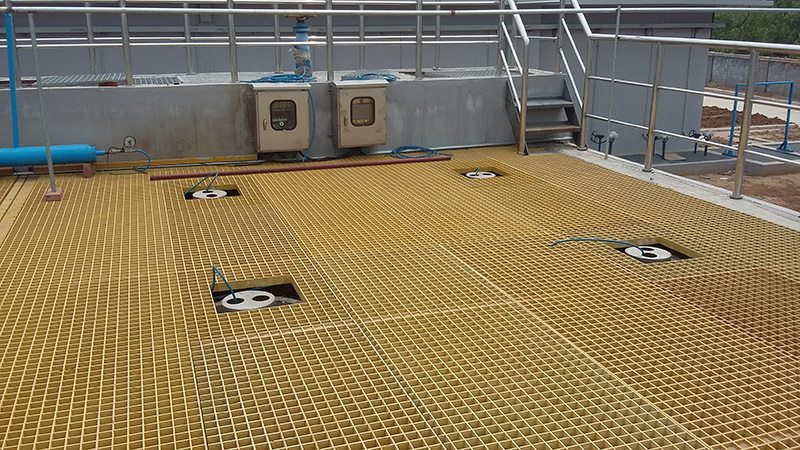

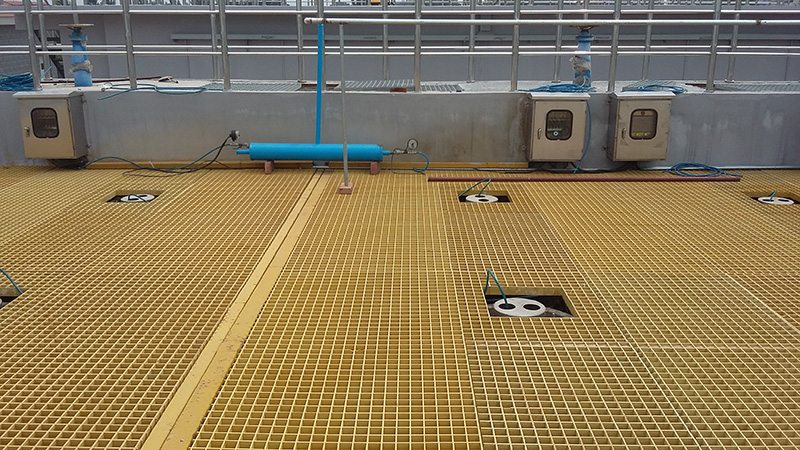

Our mission is pure water filtration a continuous process and offered the water industry a new, unique tool. When introduced in 1980, DynaSand quickly gained approval. The uninterrupted mode of operation offers users a number of advantages compared to conventional backwash filters. Today, more than 15 000 DynaSand units are in operation throughout the world. Supported by continuous application and product development, the number is steadily growing.

DynaSand unit is a continuously operating sand filter. Availability in maximized by elimination the need to take the unit out of service for backwashing. The sand is cleaned at all times by means of an internal washing system. Operation is straightforward and reliable.

♦ No first filtrate. Always clean effluent.

♦ No shock loads on the wash water treatment system.

♦ Handles high suspended solids without need for pre-treatment.

♦ Low head loss.

♦ Low energy consumption.

♦ Low supervision and maintenance cost.

♦ No need for backwash pumps.

♦ No wash water storage tanks.

♦ No wash water collecting tanks.

♦ No automatic valves.

♦ No air scour blower.

♦ No clogging filter bottom nozzles.

♦ Single Media filter bed.

The DynaSand filter is based on the counter flow rinciple.The water to be treated is admitted through the inlet distributor (1) in the lower section of the unit and is cleaned as it flows upwards through the sand bed, prior to discharge through the filtrate outlet (2) at the top. The sand containing the entrapped solids is conveyed from the tapered bottom section of the unit (3), by means of an airlift pump (4), to the sand washer (5) at the top. Cleaning of the sand commences in the pump itself, in which impurities are separated from the sand grains by the turbulent mixing action. The contaminated sand spills from the pump outlet into the washer labyrinth (6), in which it is washed by a small counter current flow of clean water. The separated solids are discharged through the wash water outlet (7), while the grains of clean sand (which are heavier) are returned to the sand bed (8). As a result the bed is in slow, constant downward motion through the unit. Compressed air for the sand pump is provided via the control panel (9). Thus, water purification and sand washing both take place continuously, enabling the filter to remain in service without interruption.

| Model | Filter area (m²) |

Filter layer Depth (m) |

Volume (m3/h) |

Diameter (mm) |

Wastewater discharge (%) |

Equipment height (mm) |

Maximum air consumption m³/h(0.4MPa) |

| WL-05 | 0.5 | 1.5-2.0 | 3~5 | 800 | 5-10 | 3500~4000 | 2 |

| WL-10 | 1 | 1.5-2.0 | 5~10 | 1150 | 5-10 | 4300~4800 | 2.5 |

| WL-15 | 1.5 | 1.5-2.0 | 10~15 | 1400 | 5-10 | 4600~5100 | 3 |

| WL-20 | 2 | 1.5-2.0 | 15~20 | 1600 | 5-10 | 5000~5500 | 4 |

| WL-30 | 3 | 1.5-2.0 | 20~30 | 2000 | 5-10 | 5400~5900 | 6 |

| WL-40 | 4 | 1.5-2.0 | 30~40 | 2260 | 5-10 | 5800~6300 | 8 |

| WL-55 | 5.5 | 1.5-2.0 | 40~55 | 2650 | 5-10 | 6200~6700 | 10 |

| WL-60 | 6 | 1.5-2.0 | 55~60 | 2770 | 5-10 | 6500~7000 | 12 |

Top

Top